In the world of industrial operations, the efficient and safe management of sumps and tank vapor spaces is of utmost importance. These areas are prone to the accumulation of oil and other hazardous substances, posing serious risks to both workers and the environment. Traditionally, visual inspections of these areas have been carried out by human workers, who face numerous challenges and potential dangers while performing their duties. However, with the advancements in robotics technology, visual inspections can now be carried out by robots, offering a safer and more efficient solution.

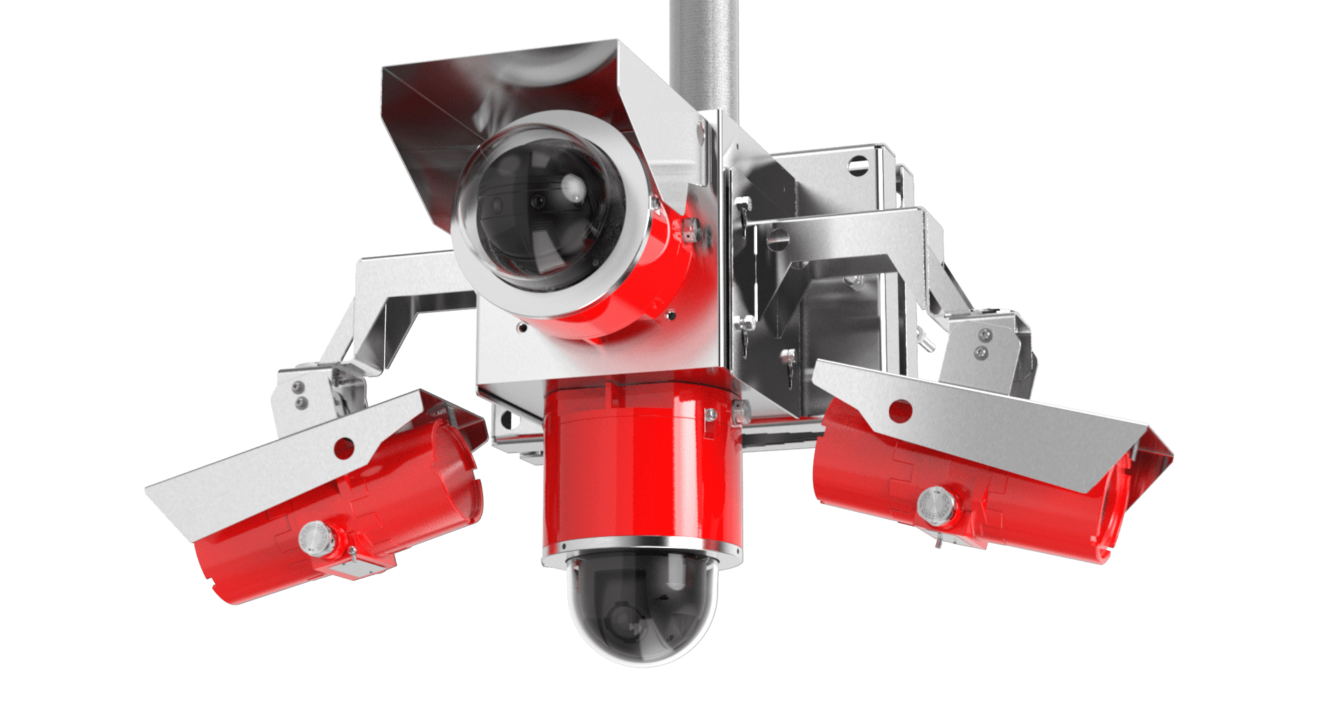

Robots equipped with cameras and sensors can access and inspect sumps and tank vapor spaces with ease, eliminating the need for human workers to enter these hazardous areas. With their ability to navigate tight spaces, robots can provide a comprehensive view of the condition of the sumps and the presence of any oil or other substances.

The use of robots for visual inspections brings several benefits. Firstly, it significantly reduces the risks associated with human entry into these areas. Workers no longer have to expose themselves to harmful substances or precarious working conditions. This not only enhances the safety of the workers but also minimizes the potential for accidents and injuries.

Secondly, robots can perform inspections more efficiently and accurately than humans. They can be programmed to follow predefined paths, ensuring that every corner of the sump or tank vapor space is thoroughly inspected. Robots can also capture high-resolution images and videos, allowing for detailed analysis of the condition of the sump or any signs of contamination.

Furthermore, robots can be equipped with advanced sensors that can detect the presence of oil and other hazardous substances. These sensors can provide real-time data on the concentration and type of substances present in the sumps or tank vapor spaces. This information can be invaluable for prompt and effective remediation measures.

Implementing robot-based visual inspections can also result in cost savings for industrial operations. By reducing the need for human workers to enter these hazardous areas, companies can save on labor costs and minimize the risks of potential lawsuits or compensation claims resulting from accidents or health issues.

It is important to note that while robots offer numerous advantages for visual inspections, they should not entirely replace human involvement. Human oversight and expertise are still crucial for interpreting the data collected by robots and making informed decisions regarding maintenance and remediation actions.

In conclusion, the use of robots for visual inspections of oily sumps and tank vapor spaces brings significant benefits to industrial operations. By eliminating the need for human workers to enter these hazardous areas, robots enhance safety, efficiency, and accuracy. They can provide real-time data on the condition of the sumps and the presence of hazardous substances, enabling prompt remediation actions. However, human oversight and expertise are still essential for data interpretation and decision-making. Embracing robot-based visual inspections can revolutionize the way industrial operations manage these critical areas, ensuring the safety of workers and the protection of the environment.